In modern smart buildings, where automation provides a high level of infrastructure management, water leakage detectors play a critical role. Water that leaks in unexpected places can cause huge financial losses, damage property, and create serious business disruptions. Without water leak monitoring, you will only be able to find out about flooding after the water has already caused damage to your property, and we analyzed the signs that indicate a water leak in the previous article. This is especially true for commercial buildings, where every hour of downtime can lead to significant losses, and for residential complexes, where damage can affect residents and their living conditions. Water leakage detectors are designed to detect even minor leaks and prevent serious accidents quickly.

Thanks to advancements in IoT and automation technologies, water leakage sensors are practically a must-have in today’s modern buildings. The incorporation of such sensors in smart control systems facilitates leak detection and prevention before they do any harm. IoT, on the other hand, allows for real-time communication between sensors and devices, meaning that an owner or manager will be able to deal with the issue at hand as it occurs. This improvement in maintenance strategy not only prevents a lot of damage but also minimizes maintenance expenditure, making water leak detectors essential components for automated systems in buildings.

Flood Sensors or Puck Sensors

Flood sensors, also known as “pucks” or puck sensors, are one of the most common sensors for detecting water leaks in smart buildings. They are usually small and can be easily installed in the most vulnerable places to leaks, such as under sinks, around water heaters, or under appliances such as dishwashers and washing machines. The basic idea is to have sensors where water can potentially accumulate to detect the problem and quickly minimize the risk of damage.

These sensors are essentially “point” sensors that respond to contact with water. The simplest of them are equipped with built-in sirens that alert you to a leak with a loud sound. However, more modern options also include wireless connectivity, allowing the system to transmit real-time leakage notifications via Wi-Fi or Bluetooth to smartphones, control panels, or directly into a centralized building management system, such as the one we discussed earlier. This makes it possible to manage the issue even remotely, which is especially important for commercial facilities or apartment buildings.

Functionality

Puck sensors work on a fairly simple principle: when water reaches the sensor electrodes, it is activated and notifies the user. To do this, they usually have special metal contacts on their lower part that close the electrical circuit when in contact with water. Simple models are equipped with audible sirens that signal the problem immediately on the spot. More advanced models can transmit information over wireless channels such as Wi-Fi, Bluetooth, or even LoRaWAN, allowing the system to send real-time alerts to building managers or homeowners.

Alternatively, such sensors can be part of a larger smart home system, where leak alerts are sent to a phone or cloud service, allowing for a response even without being physically present at the scene. Many systems have integration with other smart devices, such as automatic water shut-off valves, which can shut off the water supply automatically in the event of a serious threat.

Usage options

In residential and commercial properties where the chances of water leaks are numerous, puck detectors are very convenient. They are usually placed in the high-risk areas of laundry rooms, kitchens, boiler houses, or around heat systems. In the case of apartment buildings, such sensors are helpful in the timely prevention of leak damage to property, as well as keeping the residents safe from accidental incidents. In office blocks, such devices may be used in commercial kitchens, server rooms, or anywhere that water is employed for cooling purposes.

Advantages

The main benefit of such sensors is the fact that they are inexpensive and easy to operate. These sensors can be fitted without the need for any special resources, and self-contained models use standard batteries, enabling leak detection systems to be set up very quickly. In addition, thanks to wireless technologies, warning signals can also be relayed almost instantly, making it possible to take timely action and avoid serious damage to properties.

Other benefits include the ability to easily integrate sensors into existing building management systems, high reliability in rooms with direct access to water (kitchens, bathrooms, etc.), easy maintenance, and low operating costs.

Disadvantages

With all the advantages, it still holds that puck-type sensors have some drawbacks. They may be incapable of identifying passive, slow, or area-covering leaks inside building components, such as walls or ceilings. The sensors have to be placed right at the location of the expected leak, or else there is a considerable chance that water might spread around and even reach different places before the sensor goes off. This causes them to be less effective in detecting leaks in areas that are more concealed and difficult to reach, such as the pipes located within the walls or beneath the floor.

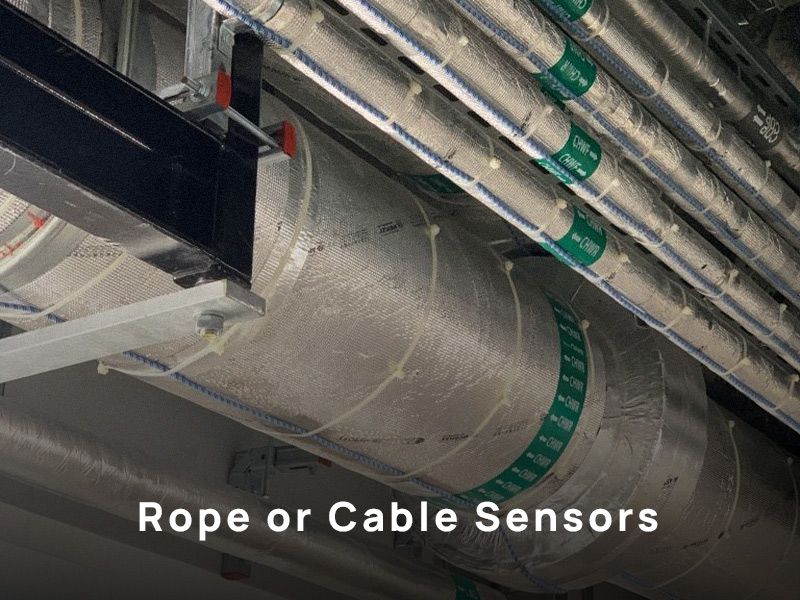

Rope or Cable Sensors

Rope or cable sensors are an efficient way for leak detection systems to cover large surfaces while ensuring multiple zones are monitored. In contrast to puck-type sensors that are triggered only by water contacting a specific point, rope sensors can detect water presence along the entire cable length. This feature facilitates their use in areas such as boiler rooms, basements, and corridors of long pipelines, where the risk of water exposure is even higher.

Such sensors, as a rule, consist of flexible tubular structures responsible for moisture detection and alarm stretching around walls, floors, or any difficult areas. Their high potential for large area coverage enables effective utilization for the protection of large rooms or areas with complex networks of pipes in warehouses and server rooms, which are highly sensitive to water damage.

Functionality

The primary idea behind rope sensors is that any point of the cable will respond to water contact. The warning mechanism is triggered as soon as water comes into contact with the wire and closes the electrical circuit. This advantage makes it possible to monitor leakages over a very large distance, thus making these sensors useful for large areas susceptible to water leakages.

Since most modern models of cable sensors can be paired with building systems or the Internet of Things, the situation can be managed remotely and alerts can be sent in real-time. This is especially important in unattended areas such as warehouses or data centers, where water can destroy devices.

Usage options

Rope or cable sensors are often applied in large buildings or buildings with complex water supply systems, which need multi-location monitoring for leaks. For example, wire rope sensors are mounted to the pipes cooling the server equipment in data centers to ensure prompt detection of the tiniest leaks, which may have adverse effects on costly equipment.

Such sensors are also used in industrial premises or warehouses where leaks can occur in different places and large areas need to be monitored. Due to their length, the cables can wrap around large areas, creating continuous protection around the perimeter or along key pipe areas.

Advantages

The area coverage provided by rope sensors is one of their greatest benefits. They come in very handy in vast structures where a water leak may have several potential locations. Since rope sensors have a wider coverage area as compared to point sensors, it lessens the number of devices required to offer complete room coverage.

An additional significant benefit is that flexible rope sensors can be placed in obscure locations or around electronics where other types of sensors would have poor placement. Because of IoT as well as remote alerting abilities, they are more effective in building management and in responding to threats.

Disadvantages

As many advantages are presented by rope sensors, there are considerable disadvantages as well. For instance, these sensors may cause false alarms due to the presence of some dust or other particles, affecting their reliability in detecting leaks. Furthermore, activated rope sensors cannot be used until they dry off, which can make them ineffective for trying to detect new leaks shortly after any previous incidents.

Also, the cost of rope sensors exceeds that of point sensors, which is discouraging to small areas or buildings that have tight budgets. On the other hand, large commercial or industrial facilities that have a significant portion of their equipment budget allocated to water leak protection will not be concerned about these shortcomings.

Printed Sensors

Printed sensors have made it easier to develop flexible and thin sensors that aid in the detection of moisture. They are setting high levels of standards and sophistication as embedded fixtures in modern building automation systems. Since they are made uniquely, it becomes possible to embed these sensors in surfaces like floors, walls, and even into construction materials, making the sensor suitable for places where aesthetics are of higher consideration. In contrast to rope or point sensors, printed sensors do not demand ample construction space and can encompass vast territories.

Innovative in their simplicity, printed sensors will automate leak detection units in smart buildings, as this technology restricts the need for strict mounting in one location. Printed sensors allow for wide area coverage and are beneficial for targeted monitoring of areas that traditional sensors may be too large or inefficient to cover.

Functionality

The functioning of printed sensors is based on polymer film technology containing conductive elements that make it possible to detect moisture over the entire area. They are mounted on surfaces and do not stand out, and, therefore, they can be used where other sensors may not only be inconvenient but are too large. A water sensor generates an alarm when a change in electrical conductivity due to water contact takes place.

When it comes to the complexity of installation and operation of printed sensors, these seem to be better than cabled sensors because narrower or irregular places do not hinder the installation of sensors. Also, these sensors are less complicated to use after activation — as a result of fast drying, they can go back to active operation which minimizes the period of inactivity of the security system after a leak.

Usage options

Printed sensors find application in various commercial establishments, in particular those where it is crucial to promptly and effectively identify water leakages. Such facilities include hospitals, shopping centers, or even high-end residential buildings which prefer this technology since the system can be effortlessly concealed within the walls or floors, hence enabling round-the-clock surveillance without disrupting the aesthetics of the interiors.

The strictest safety and precision measures when operating in medical institutions make printed sensors very appropriate for deployment in such settings. For instance, hospitals may have such sensors placed around the periphery of the operation rooms or on delicate pieces of equipment, which is quite critical in averting water damage. In shopping centers, where aesthetics have more weight, drenched sensors can be placed underneath tiles or parquet under constant pressure due to water monitoring systems.

Advantages

The greatest benefit of printed sensors is that they can be distributed across large distances without having to rely on huge cables or several sensors. Such sensors may be incorporated into floors, walls, and other constructions, making them aesthetically pleasing and suitable for any surroundings. This makes them very useful in locations where there are high design and aesthetic expectations.

Another benefit to highlight is these sensors are easily restored after coming in contact with water. After a leak, such devices can just be dried, which lowers the downtime of any system and allows continuous scanning of the environment for water leaks.

Disadvantages

While they have numerous advantages, printed sensors are still a nascent technology that can add to their costs. Furthermore, owing to the novelty of the technology, the supply in the market is still limited and not all the producers can provide a comprehensive selection of such sensors.

Even though they are highly effective, due to specific performance characteristics, sometimes printed sensors have to be deployed in further protection systems, or false alarms tend to occur in very humid surroundings. However, taking into account the fast pace of technological evolution, it can be anticipated that these sensors will be cheaper and more functional in the future.

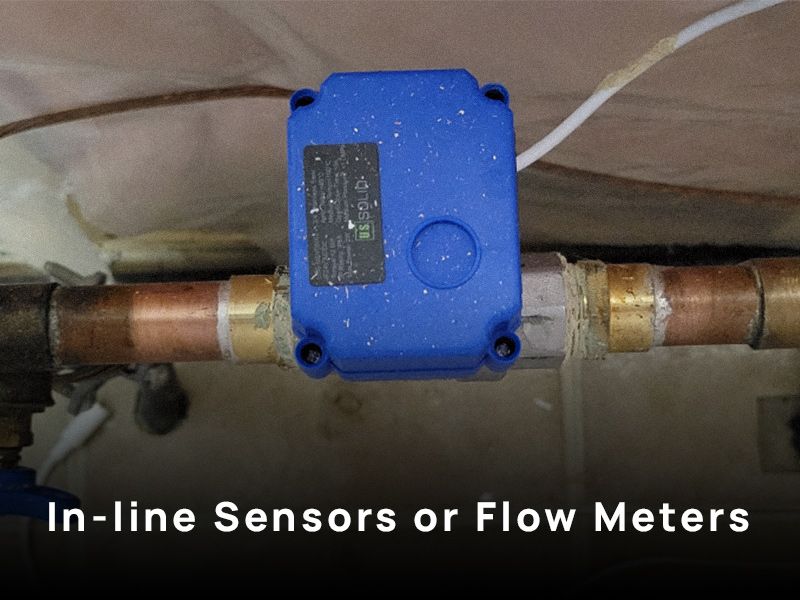

In-line Sensors or Flow Meters

In-line water leakage sensors, called flow meters, allow for the monitoring of the water supply when there is no contact possible with the water body. Rather than measuring the presence of water in the monitored area, as point or rope sensors do, they measure pressures and flow rates remotely at various points along the piping system. The sensors may alert of a shortage, an abnormal supply, or damage in the water network, which may indicate a leak or a shutdown.

Such sensors are an important component for the controlled automatic water supply of large buildings. Their major benefit is the possibility to detect leaks of water at very early stages, while inside the faucet itself. This allows for the prevention of accidents like flooding or breaking pipes in the beginning stages of development.

Functionality

Flow meters known as inline sensors are integrated within pipelines and supervise the water movement on the immediate level and include flow, volume, pressure, and other parameters. The majority of models are based on sonic measurement or simple mechanical rotors relying on water flow rates, rather than directly monitoring flow through walls of pipes or other enclosures.

The moment an abnormal situation arises, such as a fast-paced flow or drop in pressure thresholds, the unit sends an alarm message. There is a possibility of more enhanced systems with more complex algorithms, in which flow meters could cut off the water if there are significant abnormalities. It is a very useful feature that is aimed at minimizing occurrences of destruction resulting from major leaks.

Usage options

The ideal places for these sensors include extensive industries and commercial buildings that possess sophisticated plumbing systems requiring continuous surveillance of the volumetric rate of water flow, which is done by the use of flow meters. A flow meter is also useful to monitor the water mains, which can have leaks at any point in the system. Moreover, they are normally installed in extensive plumbing networks, for example, in plants and hospitals where any degree of water supply outage must be avoided satisfactorily.

As for residential complexes sharing a common water supply system, flow meters solve one more task: highlighting leaks. Even those out of sight, for instance, hidden behind walls or buried in the ground, report such situations to the main management center of the buildings.

Advantages

Detection of leaks is one of the most sought-after advantages of using flow meters. Other conventional sensors can sense just the outflow of water that has already escaped the pipes, but flow meters provide the scope to solve the problem at an early stage. Some flow meter models have the functionality of shutting off the water supply in the case of any major leaks, providing extra safety measures for the customers.

Disadvantages

However, useful – flow meters are not perfect devices. They are incapable of identifying the leak position since they only measure variations in the flow parameters. Different sensors or inspections which are not always practical can be needed to locate the exact leak. Also, such systems can be ineffective in scenarios where there are moderate leaks or slow movement of water due to seepage where no pressure fluctuations or flow rate changes exist which can ‘trigger’ the sensor.

Conclusion

Water leakage sensors in smart buildings are associated with several advantages that are difficult to over-emphasize. To start with, such sensors enhance the overall management of the building quite significantly, as they enable you to assess the chances of leaks and address them before they cause serious damage to the property. For businesses and individuals alike, this is crucial, since even minor leaks can result in huge expense outlays for repairs. Also, the detection of water leakage systems reduces wastage of water, which is not only economical but also contributes towards meeting the requirements for sustainability in today’s development.

The rise of the Internet of Things (IoT) along with the automation of systems has brought about a need to integrate water leakage detectors into the building management systems, making this more of a necessity than a mere option. Depending on the specific requirements of the building, a variety of sensor types ranging from rudimentary “washers” to advanced printed sensors and flow meters are available, and each serves its purpose and has its advantages. Choosing the proper type of sensor depending on the size of the facility, the arrangement of the premises, and the risk zones to avoid leaks is important. The reasonably accurate and dependable this decision is, the losses from the water damages will be less, and the safety and comfort of the dwellers and the employees of the building will be guaranteed.

That is why, water leakage detectors are one of the essential devices within a modern smart building whose objective is to enhance the reliability, efficiency, and safety level of the building.